Description

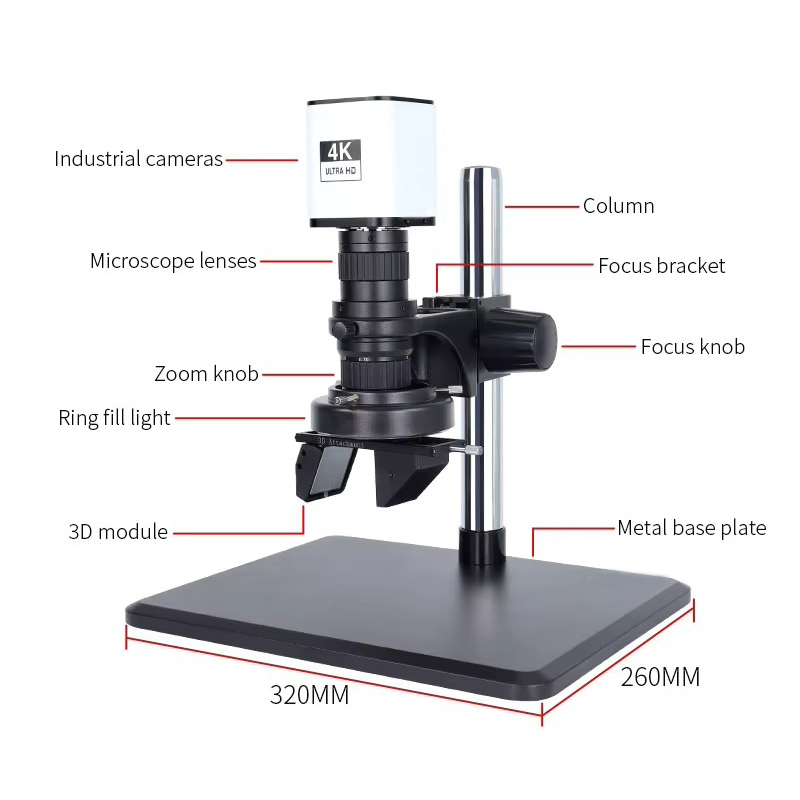

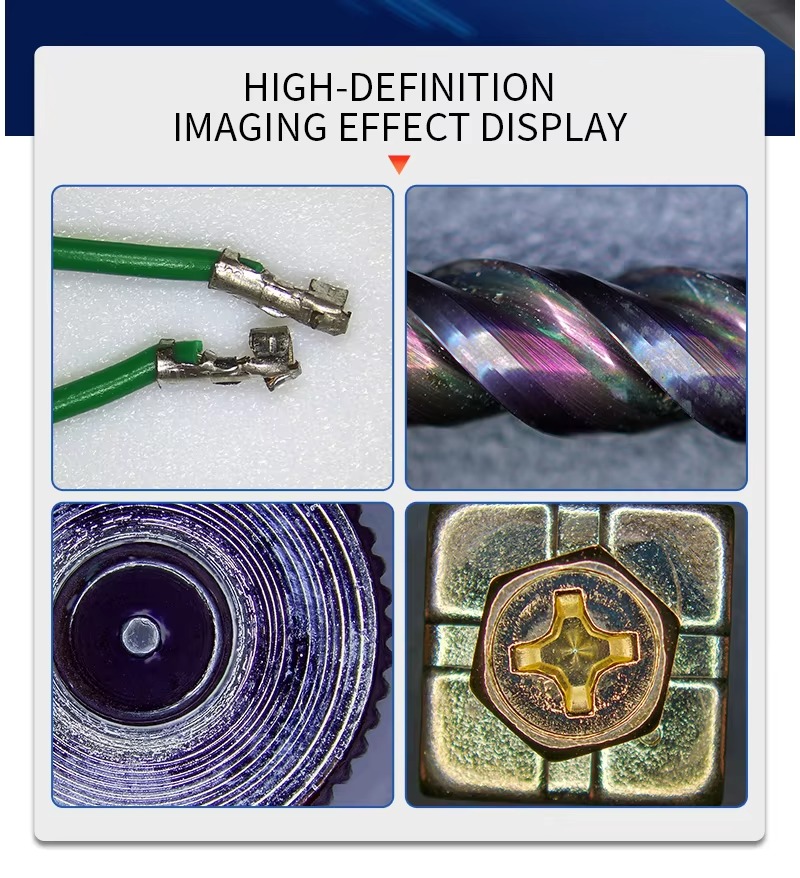

The 4K digital microscope is a versatile tool specially designed for mobile phone repair, electronics inspection, and precision soldering. Equipped with ultra-clear 4K resolution, it delivers sharp, detailed images that reveal even the tiniest components with exceptional clarity. Its dual HDMI and USB outputs provide flexible viewing options on monitors or computers, ensuring real-time display and easy documentation. With adjustable magnification and stable performance, this digital microscope enhances efficiency and accuracy, making it an essential device for technicians, repair shops, and electronic enthusiasts.

Specification of Digital Microscope for Mobile Repair

| Optical Magnification | 0.7x – 5x continuous zoom |

| Digital Magnification | 25x – 230x |

| Chipset | ARM Dual-Core Architecture |

| Sensor | 1/1.8 Inch |

| Resolution | 3840*2160P@60FPS |

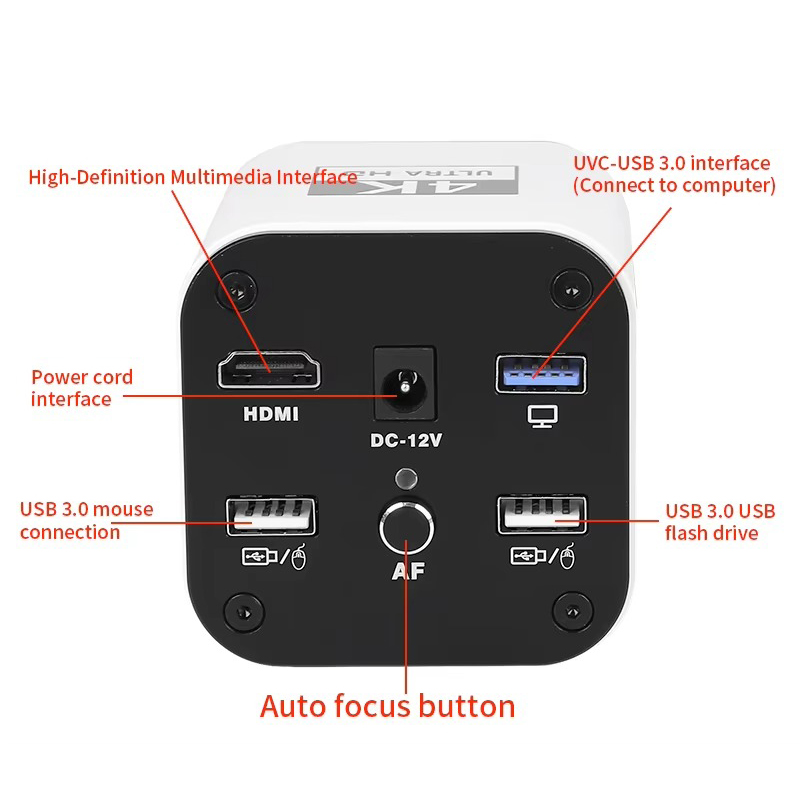

| Output Interface | HDMI + UVC-USB3.0 High-Speed Output |

| Lens Interface | C Mount |

| Power Supply | DC 12V |

| Pixel Size | 2.0μm*2.0μm |

| External Devices | HD Monitor + Computer |

| Storage Method | Supports USB flash drive storage and mouse operation |

| Import function | Supports importing pictures from USB flash drive to camera |

| Grid Lines | 8 Sets of Grid Lines (8 Selectable Colors / 4 Selectable Line Widths) |

| Basic Functions | Photo Capture, Video Recording, Measurement, Storage |

| Image Adjustment | Color, Color Temperature, White Balance, Exposure |

| Camera Features | AF Auto Focus, Frame Freeze, Auto Exposure, White Balance, Partial Zoom, HDR Wide Dynamic Range, Image Preview, Digital Zoom In/Out, Dual/Quad Split-Screen Comparison |

| Illumination Method | 56 LEDs ring light illumination |

| Menu Language | Simplified Chinese, Traditional Chinese, English |

Applications of HDMI USB 4K Digital Microscope

- Electronics & Mobile Repair – circuit board inspection, soldering, and microchip analysis

- Semiconductor Industry – wafer inspection, IC packaging, and defect detection

- Precision Manufacturing – tool wear analysis, parts inspection, and surface quality checks

- Education & Training – classroom demonstrations, repair workshops, and technical training

- Metallurgy & Material Science – microstructure study, weld inspection, and failure analysis

- Jewelry & Watchmaking – gemstone grading, setting inspection, and fine mechanical repair

Reviews

There are no reviews yet.